In today’s rapidly evolving industrial landscape, smart technologies are redefining how machines, systems, and factories operate. At the heart of this transformation are Industrial IoT (IIoT) sensors—a core component of smart manufacturing, automation, and predictive maintenance.

But what exactly are industrial IoT sensors, and why are they crucial for modern industries?

In this blog by AirAtom Smart Solution, we provide a complete introduction to industrial IoT sensors, their types, applications, and how they are shaping the future of smart industries.

What Is an Industrial IoT Sensor?

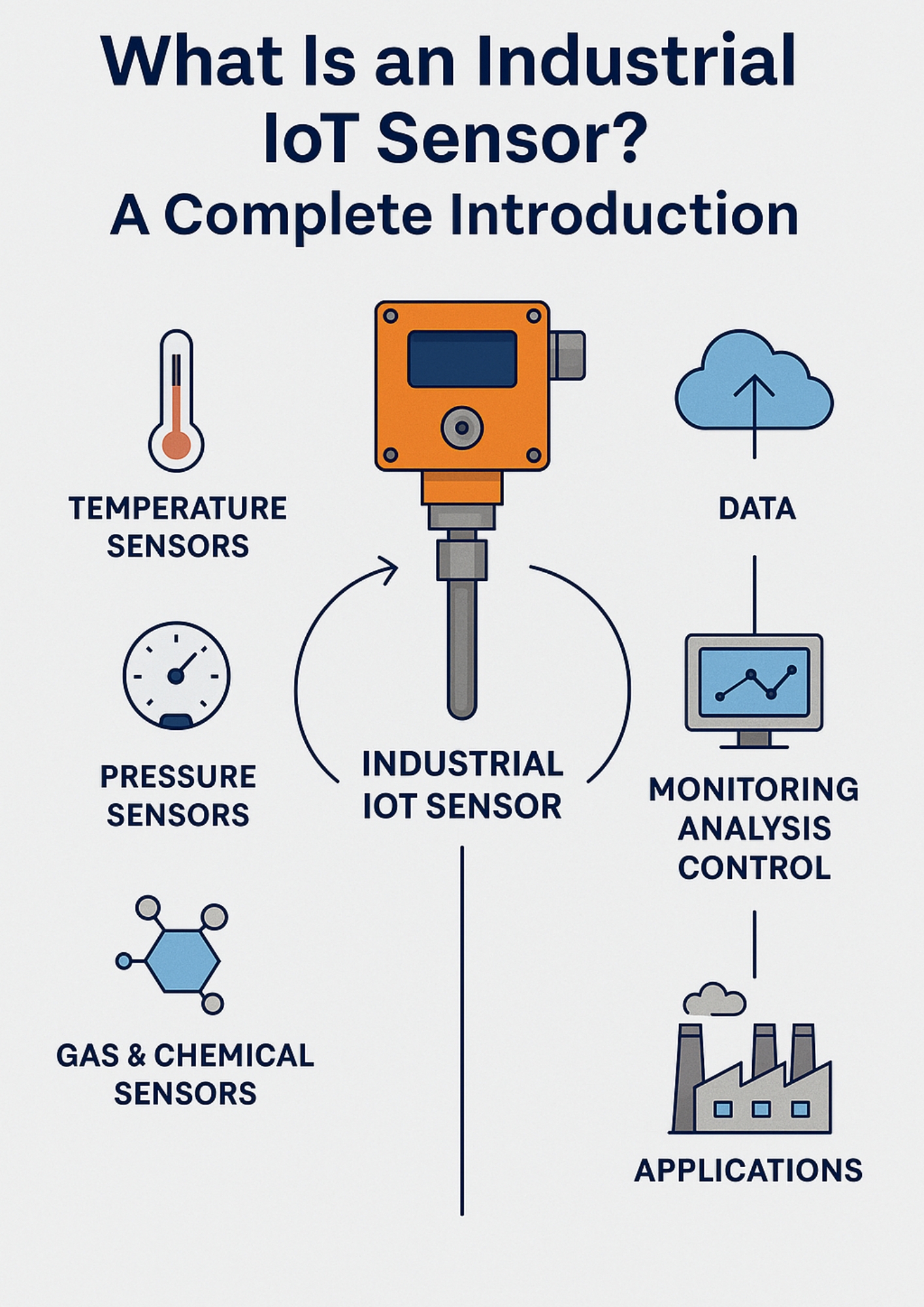

An Industrial IoT sensor is a device used in industrial environments to detect physical changes such as temperature, pressure, vibration, or motion and convert that data into digital signals. Industrial IoT sensors connect to smart networks, enabling instant data transfer to centralized platforms for continuous monitoring, in-depth analysis, and automated process control.

Unlike traditional sensors, IIoT sensors are network-enabled, meaning they can communicate data over the internet or local networks—enabling smarter, faster, and more informed decision-making.

Key Features of Industrial IoT Sensors

✅ Real-Time Monitoring

Instantly track conditions such as temperature, humidity, gas leaks, or vibration levels.

✅ Remote Access

Users can remotely access sensor data through cloud-based dashboards or mobile applications, ensuring real-time visibility from any location.

✅ Integration with Control Systems

These sensors are designed for smooth integration with industrial automation systems like SCADA, PLCs, and other control platforms, streamlining operations and decision-making.

✅ Predictive Maintenance

By analyzing real-time sensor data, industries can detect abnormal behavior early and forecast potential equipment failures, minimizing unplanned downtime.

Types of Industrial IoT Sensors Temperature Sensors Monitor temperature changes in critical environments such as boilers, ovens, or cold storage.

Pressure Sensors

Used in hydraulic systems, pipelines, and pneumatic controls.

Vibration Sensors

Essential for condition monitoring in rotating equipment like motors and pumps.

Gas & Chemical Sensors

Detect hazardous gases or leaks to ensure workplace safety.

Level Sensors

Monitor liquid or material levels in tanks, silos, or containers.

Proximity & Motion Sensors

Track object movement and enhance automation in manufacturing lines.

Why Are Industrial IoT Sensors Important?

In the era of Industry 4.0, IIoT sensors play a vital role in making industrial operations smarter, safer, and more efficient. Benefits include:

Reduced downtime through predictive maintenance

Enhanced worker safety via real-time alerts

Lower operational costs

Improved data-driven decision-making

Environment: Harsh or hazardous conditions require rugged sensors

Accuracy: Precision is critical for sensitive applications

Connectivity: Ensure compatibility with existing systems

🔍 Need Help with Smart Industrial Sensors?

Explore our full range of solutions at airatomsmartsolution.com and take the next step toward industrial intelligence.

Cart is empty

Cart is empty

Leave A Comment