-In the era of Industry 4.0, the fourth industrial revolution is redefining how factories operate, how machines communicate, and how businesses make decisions. At the heart of this digital transformation lies a critical enabler: industrial sensors. The role of sensor in industry has shifted from simple data collection tools to intelligent components that drive automation, efficiency, and innovation.

In this blog from airatomsmartsolution.com , we explore how industrial sensors are shaping Industry 4.0 and why their influence is only growing.

Understanding Industry 4.0

Before we explore the role of sensor in industry, it’s important to understand what Industry 4.0 really means. Industry 4.0 is the integration of digital technologies such as the Internet of Things (IoT), artificial intelligence, machine learning, and big data into manufacturing and industrial processes. It connects machines, systems, and humans to create smart factories that can adapt, optimize, and make decisions in real-time.

What Are Industrial Sensors?

Industrial sensors are devices that detect changes in physical conditions—such as temperature, pressure, humidity, proximity, vibration, and gas levels—and convert them into readable signals. In the context of Industry 4.0, these sensors are IoT-enabled, meaning they can send and receive data across a network, enabling real-time monitoring and control.

The role of sensor in industry today goes beyond measurement—they are the eyes and ears of smart manufacturing environments.

The Critical Role of Sensor in Industry 4.0

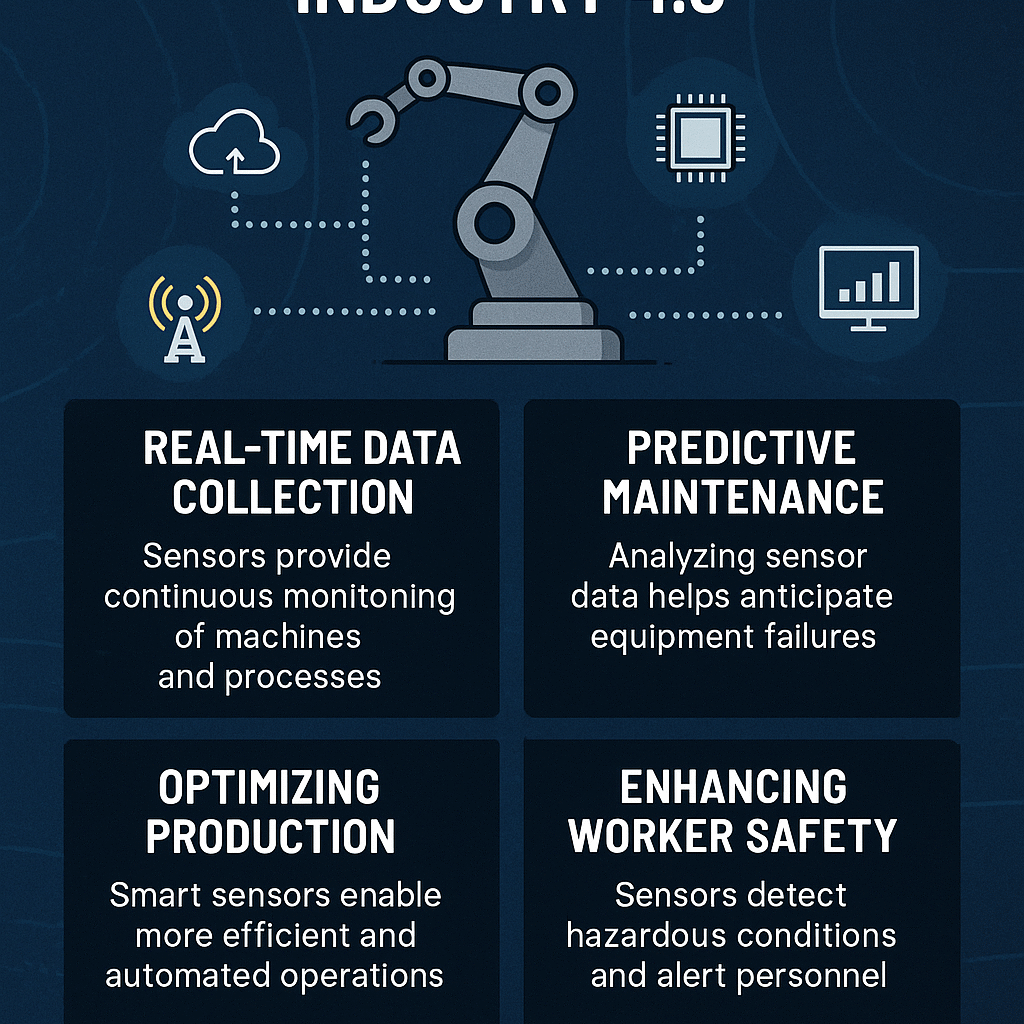

1. Enabling Real-Time Data Collection

2. Driving Predictive Maintenance

3. Optimizing Production Efficiency

4. Enhancing Worker Safety

5. Powering Smart Automation

One of the most vital aspects of Industry 4.0 is real-time data. The role of sensor in industry is to provide continuous feedback on machine performance, environmental conditions, and product quality. This real-time data helps companies respond instantly to any changes in the production line, improving both safety and efficiency.

The role of sensor in industry extends to maintenance strategies. By analyzing vibration, temperature, and load data, sensors can detect early signs of machine wear or failure. This allows companies to shift from reactive to predictive maintenance, reducing downtime and costly breakdowns.

Sensors help monitor every stage of the manufacturing process. From material input to final output, the role of sensor in industry is to ensure every parameter is optimized. This leads to increased throughput, less waste, and better resource management.

Industrial environments can be hazardous. Sensors that detect gas leaks, temperature spikes, or equipment malfunctions play a critical role in preventing accidents. The role of sensor in industry includes protecting human lives through automation and alerts.

Industry 4.0 thrives on automation, and automation thrives on data. The role of sensor in industry is to feed this automation with accurate, real-time data that allows robots, PLCs, and SCADA systems to function intelligently.

Types of Industrial Sensors in Industry 4.0

Understanding the role of sensor in industry also means recognizing the different types of sensors and their functions:

–Temperature Sensors: Monitor heat levels in machines and environments

–Pressure Sensors: Measure fluid or air pressure in systems

–Proximity Sensors: Detect object movement or positioning

–Gas Sensors: Identify harmful gas leaks or environmental conditions

–Vibration Sensors: Track mechanical movement to predict equipment failure

–Level Sensors: Measure liquid or material levels in tanks and containers

Each of these contributes uniquely to the role of sensor in industry, providing valuable insights and control.

How AirAtom Smart Solution Is Leading the Way

At AirAtom Smart Solution, we understand the vital role of sensor in industry and provide advanced sensor technologies that align with the needs of Industry 4.0. Our solutions are designed to deliver precision, reliability, and seamless integration with modern industrial control systems.

Whether you are looking to build a smart factory from scratch or upgrade your existing systems, we provide tailored sensor solutions for every industrial application.

The Future of Industry 4.0 and Sensor Technology

As Industry 4.0 continues to evolve, the role of sensor in industry will become even more central. With the rise of artificial intelligence and edge computing, sensors will not only collect data but also process and act on it at the source. This shift will enable faster decisions, decentralized control, and greater efficiency.

Moreover, with the increasing importance of sustainability, the role of sensor in industry will include monitoring energy usage, emissions, and environmental impact—helping companies meet regulatory standards and achieve green goals.

💡 Ready to Transform Your Factory?

Explore our full range of industrial sensors at airatomsmartsolution.com and see how we can empower your Industry 4.0 journey today.

Cart is empty

Cart is empty

Leave A Comment